Case Study: Energy Efficient High Lift Pump

Location:

Water Treatment Site, Troyswood

Description

Troyswood Water Treatment plant has a capacity of 6,000m3 per day. There were two lift pumps – duty and standby operating on-site. In 2010, Carlow Kilkenny Energy Agency (CKEA) carried out an energy audit of the Water Treatment Plant at Troyswood. The aim of the audit was to provide recommendations to reduce the on-site energy consumption. A number of recommendations were made by CKEA. In 2010, the low lift pump was rescheduled and in April 2011 a replacement high lift pump was installed to replace the duty / standby pump operation.

In March 2012, the main centrifuge in the plant was replaced. However, the replacement model was an older model and probably less efficient than the one it replaced.

Results

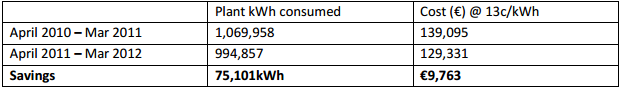

Plant consumption data was analysed before and after the installation of the high lift pump in 2011.

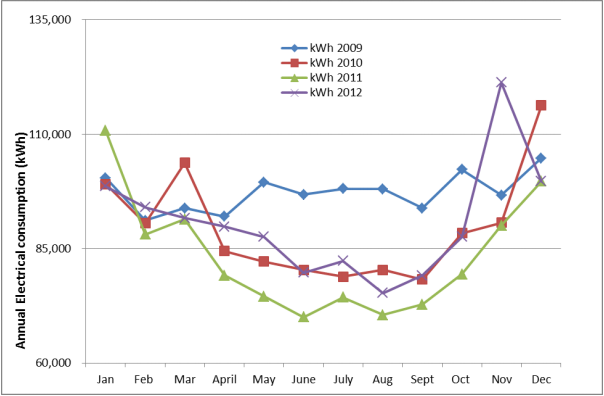

Figure 1: Annual kWh Consumption

There was a drop in plant annual energy consumption between 2009 and 2011. During this period the low lift pump was rescheduled and the high lift pump was replaced.

Annual savings – before and after of high lift pump installation

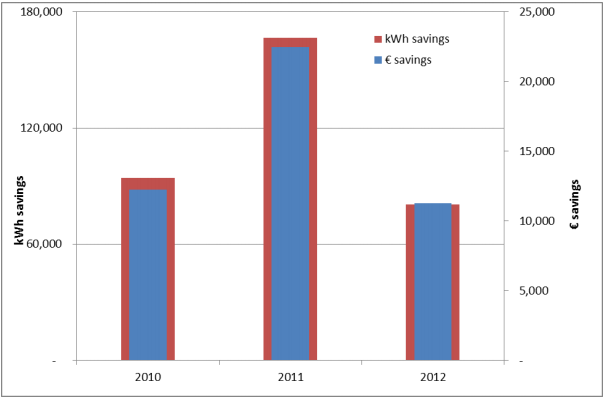

In 2012, the main centrifuge was replaced with an older model. Energy consumption increased for this year and therefore energy savings decreased. This may have been due to the installation of an older centrifuge which may have been less efficient.

In 2012, there was a drop in energy and cost savings. This is when the older model was installed as a replacement to the centrifuge.